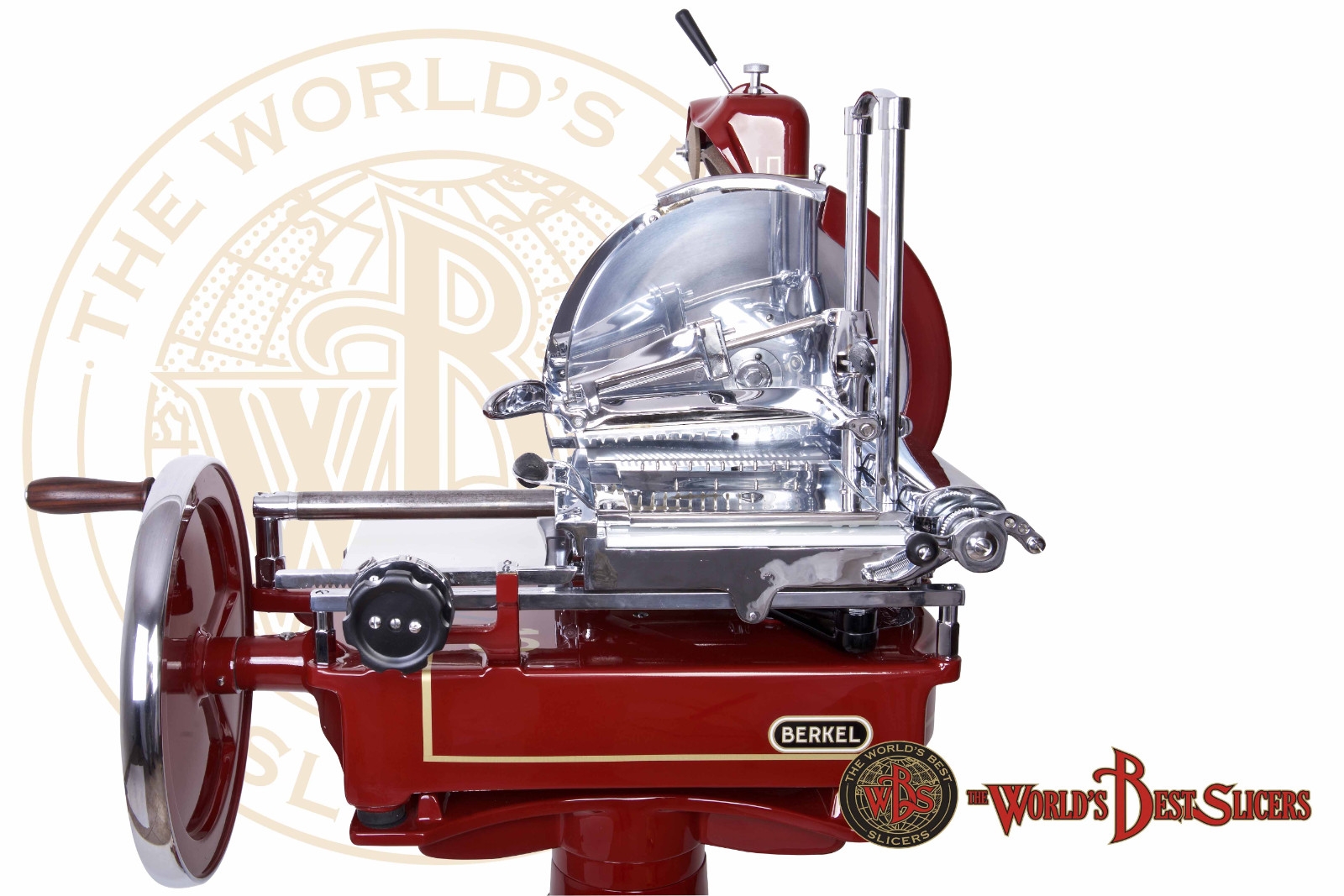

Berkel Europe Model 10

The flywheel slicer Berkel model 10 was built in the period between 1944 and 1948 in the Italian factory of “The Auto Scale & Slicing Machine”, the company that at the time was responsible for importing Berkel slicers.

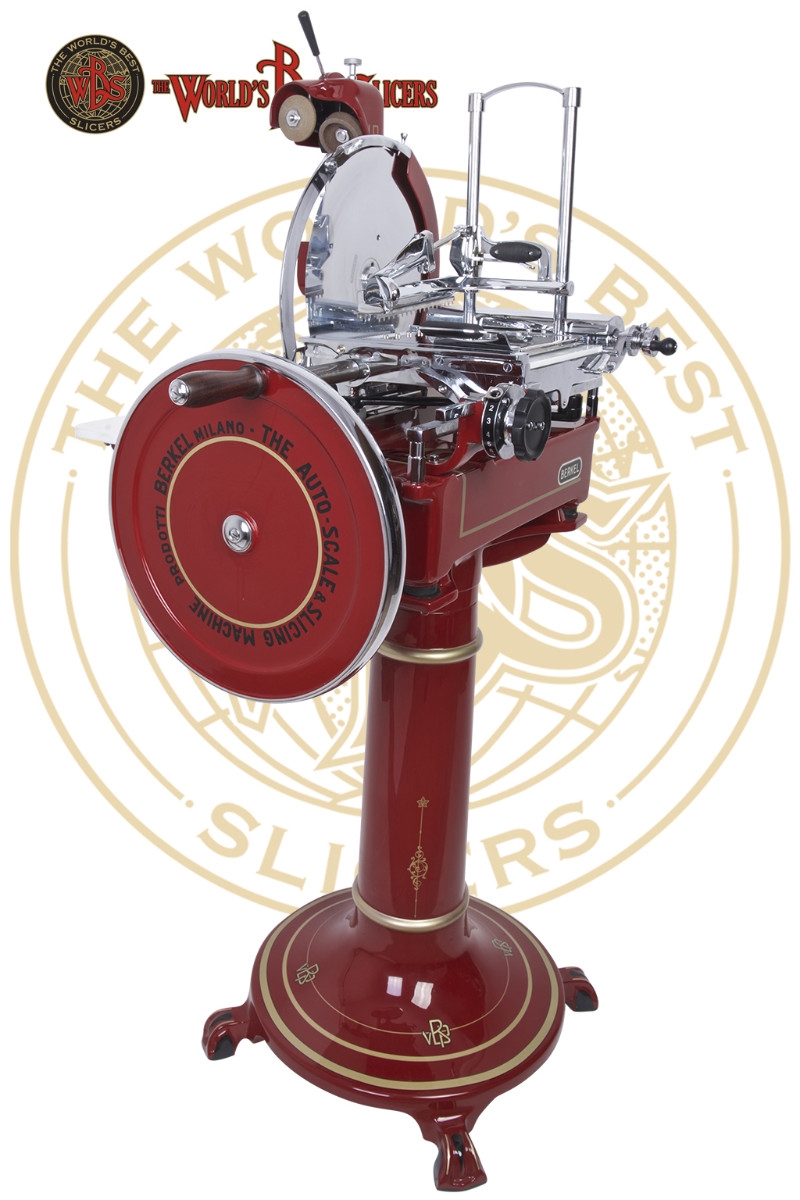

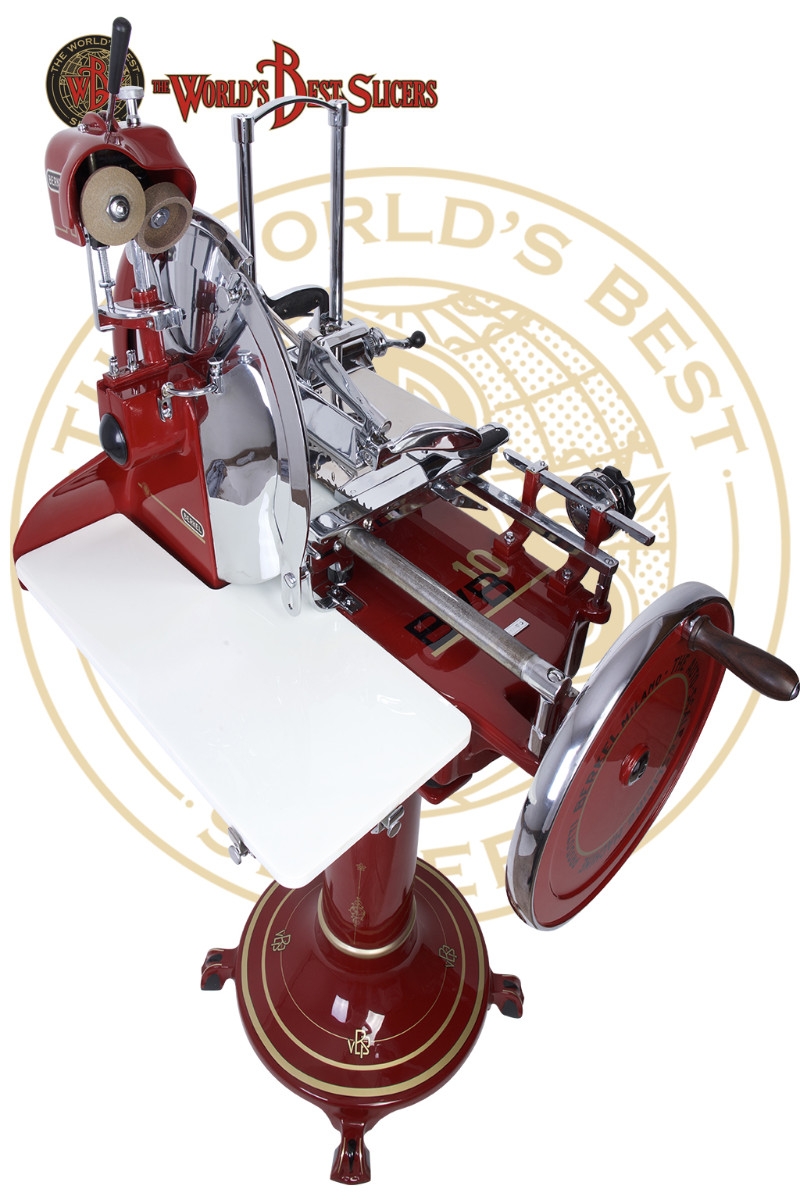

Berkel Europe Model 10

The flywheel slicer Berkel model 10 was built in the period between 1944 and 1948 in the Italian factory of "The Auto Scale & Slicing Machine", the company that at the time was responsible for importing Berkel slicers. The slicer Berkel model 10 uses a 370 mm blade. The manual operation of the machine is via a closed flywheel with an external diameter of 380 mm. and inside we can see the writing applied and executed in decal "The Auto Scale & Slicing Machine", while in the first part of the production a flywheel of the Italian version of the Berkel model 7 with embossed lettering . The slicer Berkel model 10 is provided with an accurate adjustment of the slice thickness to 15 with a snap-action clock and has a covering to protect the worm without addition to the automatic slicer, and has many features both in form and in the mechanics of the Berkel model 7. The trolley on the right side strip on the chrome rail by the application of a felt that is lubricated by oil. The Berkel Model 10 slicer features an open-type articulated arm and stainless steel plate plate and has a total carriage travel of 310 mm. The Berkel #model 12 slicer was originally painted in red and the metal parts were originally chrome, while the parts were originally painted in red, metallized gray and black, while in the restoration phase we repeat the original colors. The Berkel model 10 slicer requires a 250 mm support. front - 320 mm. rear - 460 mm. length having a total space of 660 mm. in height - 750 mm. in length - 640 mm. in width. The Berkel model 10 slicer has a net weight of 100 kg.The slicer was supplied without any supporting support, but optionally at the request of the buyer his original pedestal was supplied, where the slicer could be correctly positioned in every point of the room without creating impediments on the work and be cleaned more easily and be enhanced even more. This slicer, like all the flywheel slicers that have been restored and sold by The WBS , is restored exclusively with the exclusive use of original antique decals respecting the color tone and supplied with its original pedestal, avoiding trivial copies. The restoration is carried out in the laboratories of "The World's Best Slicers" respecting the principle of conservation of the parts. Providing for the disassembly and recovery without any replacement of the worn or broken pieces, carrying out a carryover of material by welding and subsequent milling or turning of the pieces in order to bring them back to their original dimensions and their functionality. For the missing parts, original spare parts acquired from the production plants or incomplete slicers are used. The painted parts, which were first stripped by cryo-stripping and carefully prepared, are painted using new generation paints that comply with health and pollution regulations and reformulated in the correct shade of color used in the past. The decorations are strictly performed through the application of copal paint decals, avoiding any type of mystification, such as airbrush decorations, stickers or any other type of fantasy decoration. Each restored slicer is delivered with an #Official Certificate of Originality and #Guarante