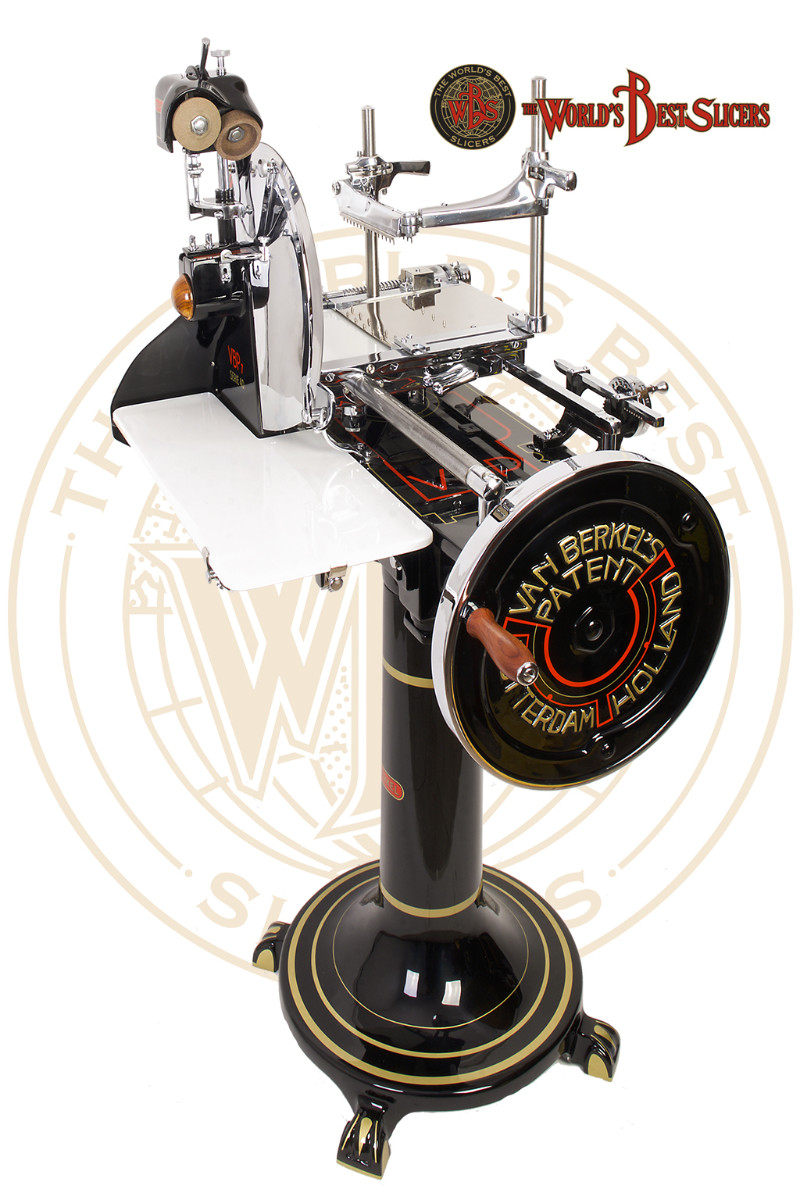

Berkel Europe Model 7 Black

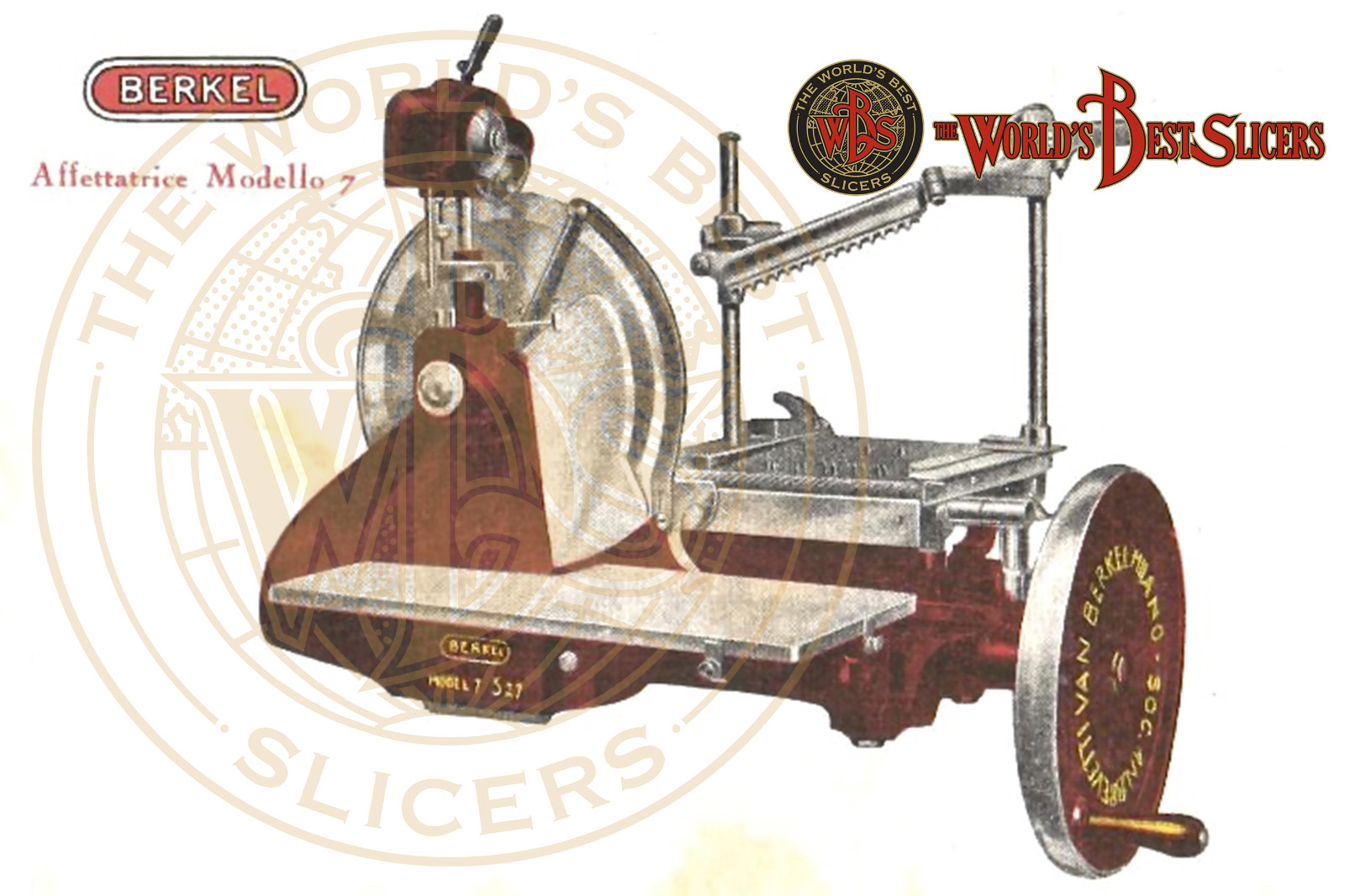

The Meat Slicer model 7 is built in the period between 1922 and 1928. The Meat Slicer Berkel Mod.7 is the second model which is also assembled in the italian fatories of van Berkel’s patent Italy. This is a variant of the Berkel slicer model 5 The arm for fixing the cured meat in the Italian variant is open in the direction of the flywheel to allow to fix even faster products of greater length.

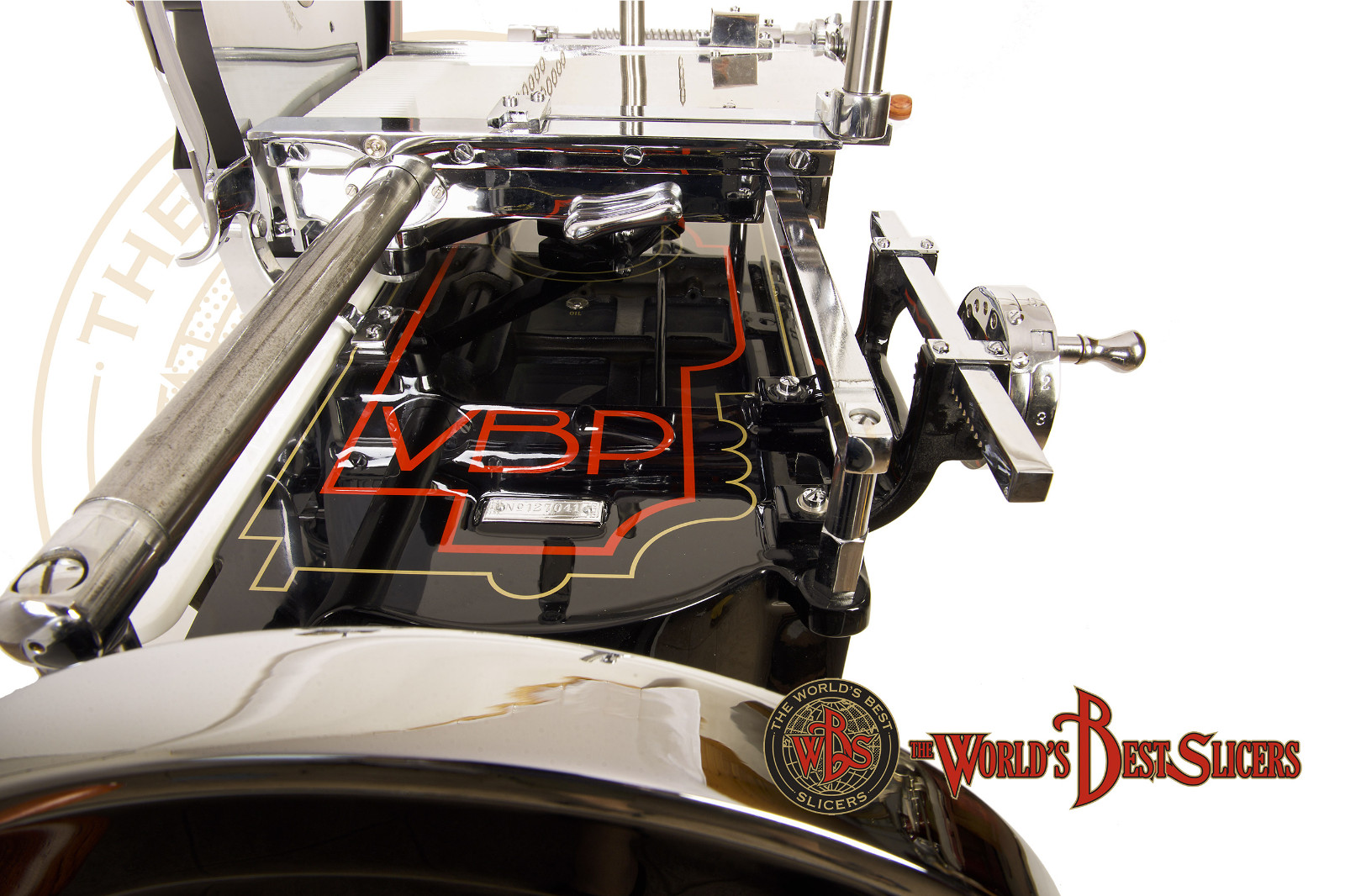

Berkel Europe Model 7 Black

The Meat Slicer model 7 is built in the period between 1922 and 1928. The Meat Slicer Berkel Mod.7 is the second model which is also assembled in the italian fatories of van Berkel's patent Italy. This is a variant of the Berkel slicer model 5 The arm for fixing the cured meat in the Italian variant is open in the direction of the flywheel to allow to fix even faster products of greater length. The Meat Slicer Berkel Mod.7 has a thickness adjustment to 15 positions slice. The Meat Slicer Berkel Model 7 was originally painted in red, black and ivory The Meat Slicer Berkel Mod.7 needs a support of 250 mm. Front - 300 mm. Rear - 460 mm. length having a total size of 660 mm. height - 840 mm. in length - 620 mm. in width. The Meat Slicer Berkel model 7 has a net weight of 105 kgThe Meat slicer Berkel model 3 is built in the period between 1915 to 1924 in Rotterdam and marketed in the Italian market from Bach & co. -P.zza Cavour, Milano. Unlike previous Berkel model 2 use the Sharpener careened closed, in the first series use a bladeof 350 mm., while later a blade of 370 mm. The machine working by a flywheel with floral design and external diameter different from the period and market where was sales . 357 mm. for the italian market embossed with the words “Berkel’s Patent Rotterdam”. 399 mm. for the first series with the inscription “van Berkel’s Patent Rotterdam Holland” while for the second series 394 mm. with the embossed inscription “van Berkel’s Patent Rotterdam Holland”.The restoration is carried out in the laboratories of "The World's Best Slicers" respecting the principle of conservation of the parts. Providing for the disassembly and recovery without any replacement of the worn or broken pieces, carrying out a carryover of material by welding and subsequent milling or turning of the pieces in order to bring them back to their original dimensions and their functionality. For the missing parts, original spare parts acquired from the production plants or incomplete slicers are used. The painted parts, which were first stripped by cryo-stripping and carefully prepared, are painted using new generation paints that comply with health and pollution regulations and reformulated in the correct shade of color used in the past. The decorations are strictly performed through the application of copal paint decals, avoiding any type of mystification, such as airbrush decorations, stickers or any other type of fantasy decoration. Each restored slicer is delivered with an Official Certificate of Originality and Guarantee