Berkel England Model M

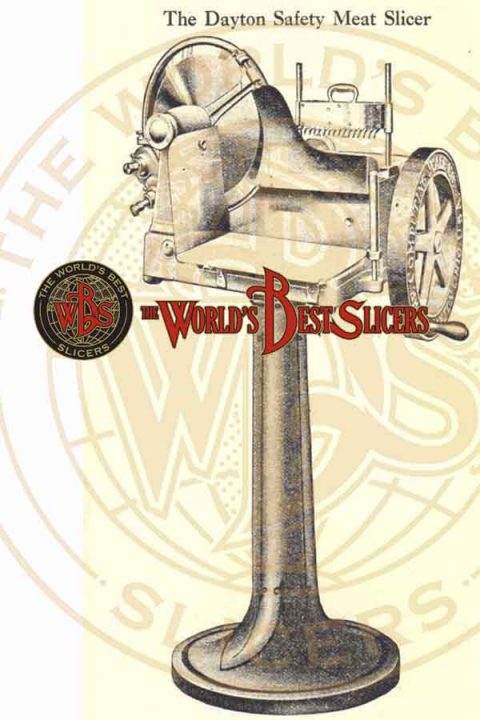

The Flywheel slicer model M was built in the period between 1907 and 1910 in the English factory of Berkel’s & Parnall’s in London. The movement is driven by the flywheel that has concentric circles that intersect to form a floral design, with the relief writing Berkel’s & Parnall’s Slicing Machine mf. co. ltd London.

Berkel England Model M

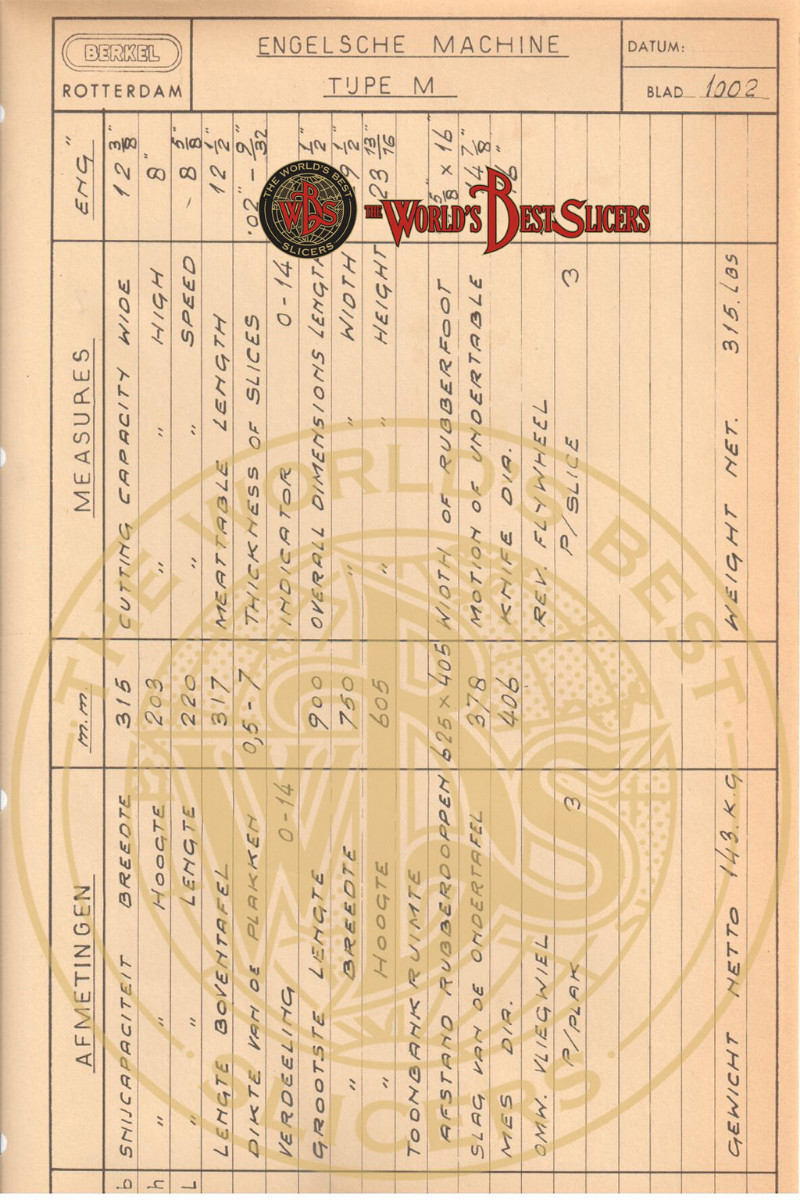

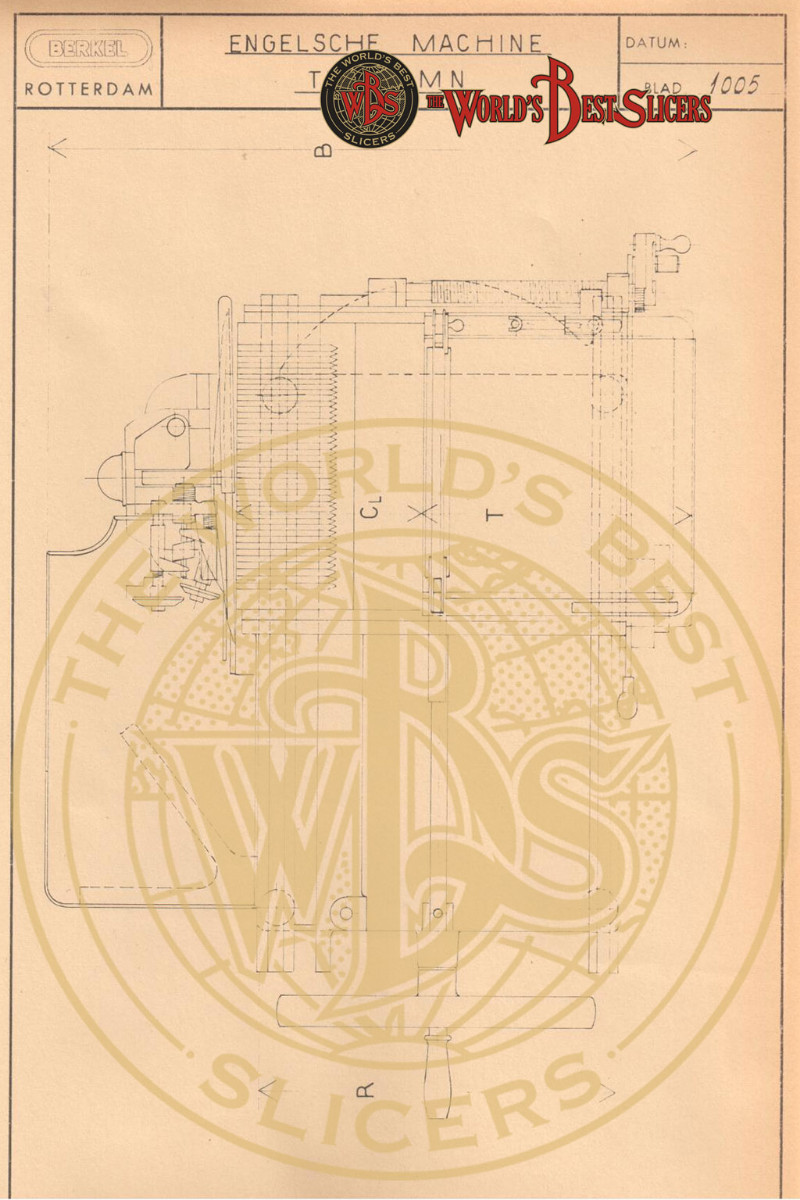

The Flywheel slicer model M was built in the period between 1907 and 1910 in the English factory of Berkel's & Parnall's in London. The movement is driven by the flywheel that has concentric circles that intersect to form a floral design, with the relief writing Berkel’s & Parnall's Slicing Machine mf. co. ltd London. The professional slicer model M, despite the abundant century of age, after a meticulous and accurate professional restoration, manages to obtain a cutting fineness of 0.2 mm. The flywheel activates the gear system that moves the blade and two connecting rods hidden under the body of the slicer that normally rests on its original period pedestal. The trolley rests on four metal wheels that slide on guides on the body of the slicer made of black bakelite. The arm, or press used for fixing the product to be cut has its movement between two opposite racks. The slice thickness adjustment is performed by a graduated numbered rod with 14 positions that slides through a slot on the right side of the trolley, connected by a small lever to the gear that creates the displacement of the plate where the product to be cut is fixed .On the plate where the product intended for cutting is fixed, the comb is fixed directly to view, which serves for the regular movement of the product towards the blade through the movement of the worm screw, provided unlike the european model L the quick release through a system that runs on two small columns. Characteristic is also the sheet metal in the upper part of the slicer block, which is present only in some of the first models produced by Berkel in black, indistinctly from the color of the rest of the machine, where a gold-colored fine box is decorated and in the part opposite the abbreviated logo of the VBP manufacturer is flying in a red-green and white decal. The blade, 406 mm. in diameter, the largest mounted on a flywheel slicer, is mounted on a shoulder whose lower part is round and to which the metal glove box is fixed to support the cut product and in the lower part a rounded shape, through two screws a plate is placed, with a drawing and description VBP of Van Berkel's Patent. In the upper part of the shoulder we find the sharpener of the blade, composed of several nickel-plated pieces, all visible and without covers. The Berkel flywheel slicer model M is considered a professional flywheel slicer. It has a total size of 900 mm x 750 mm, is 605 mm high and weighs 143 kg. The slicer needs a support of 625 mm front. X 405 mm. The Berkel slicer model M was produced in red and the metal parts are nickel-plated.The restoration is carried out in the laboratories of "The World's Best Slicers" respecting the principle of conservation of the parts. Providing for the disassembly and recovery without any replacement of the worn or broken pieces, carrying out a carryover of material by welding and subsequent milling or turning of the pieces in order to bring them back to their original dimensions and their functionality. For the missing parts, original spare parts acquired from the production plants or incomplete slicers are used. The painted parts, which were first stripped by cryo-stripping and carefully prepared, are painted using new generation paints that comply with health and pollution regulations and reformulated in the correct shade of color used in the past. The decorations are strictly performed through the application of copal paint decals, avoiding any type of mystification, such as airbrush decorations, stickers or any other type of fantasy decoration. Each restored slicer is delivered with an Official Certificate of Originality and Guarantee